MarinTrust is aware of the existence of a wide variety of other fishery and factory Standards and Benchmark Tools. Our recognition procedure outlines the process by which equivalence can be determined.

By enabling the recognition of other Standards or Benchmark Tools, we are able to:

- reduce unnecessary assessment and/or audit duplication

- reduce the audit duration for certificate holders and applicants

- reduce cost for certificate holders and applicants

- ensure increase market access for Marine ingredients.

Version 2.0 of the recognition procedure will be effective from 1st May 2024 and will supersede and replace V1.0 issued April 2018.

For further information on transition guidance, please click here.

Recognition of equivalence process

MarinTrust outlines the process and methodology to be implemented for Standard / Benchmark Tool requirements to be recognised. Key stages include:

- Stage 1 - Initiation of recognition of equivalence process

- Stage 2 - Self-assessment

- Stage 3 - Third-party equivalency assessment

- Stage 4 - Recognition decision and update of documentation

Further information on what these stages entail is outlined below.

Stage 1: Initiation of recognition of equivalence process

Equivalence determination can be initiated by:

- MarinTrust

- Relevant stakeholders

- Standard owners

- Benchmark Tool owners

Where MarinTrust is not the initiator of the equivalence determination:

- The Standard / Benchmark Tool owner must contact MarinTrust to notify their intent.

- MarinTrust will then share all documents and templates for self-assessment.

Stage 2: Self-assessment

- Standard / Benchmark Tool owner conducts self-assessment and submits to MarinTrust.

- Standard / Benchmark Tool owner pays self-assessment recognition review fee.

- Third-party conducts review of self-assessment and offers recommendation to MarinTrust.

- MarinTrust reviews recommendation and shares outcome with Standard / Benchmark Tool owner.

Note: Standard / Benchmark Tool owners will only proceed to Stage 3 provided the self-assessment outcome is 'recognition process recommended'.

Stage 3: Third party equivalency assessment

- The Standard / Benchmark Tool owner must pay the equivalency assessment fee invoice.

- Third party conducts equivalency assessment and shares draft report with the Standard / Benchmark Tool owner.

- Standard / Benchmark Tool owner addresses comments within a two-week comment period from receipt.

- Third party considers feedback and finalises the equivalency report and recommendation.

- Third party submits documentation and offers recommendation to MarinTrust.

Stage 4: Recognition decision and update of documentation

Where recognition is successful, MarinTrust will:

- Inform Standard / Benchmark Tool owner of the completion of the equivalency assessment exercise and recommended outcome.

- Present the results of the equivalency assessment to the Governing Body Committee (GBC) for recommendation of approval of the outcome at the next scheduled GBC.

- Notify the Standard or Benchmark Tool owner of the final approval decision of the GBC either to formally recognise or not to formally recognise.

- Publish the equivalency report on the MarinTrust website and update all relevant information.

What happens after achieving recognition?

Following successful recognition, Standard / Benchmark Tool owners will be required to maintain the equivalence status.

Maintenance and review of equivalence status

To maintain equivalence status, a process of periodic review will be carried out.

The Standard and/or Benchmark Tool owner must:

- Notify MarinTrust via [email protected] of any changes to status in baseline requirements and requirements within the scope of recognition.

- Submit an annual declaration form to MarinTrust.

- Pay relevant annual recognition fees.

For further detailed information, please refer to Recognition of equivalence procedure.

Programmes/Standards currently recognised

The four Standards formally recognised under the MarinTrust Programme are:

- Programa de Aseguramiento de la Calidad (Chilean PAC)

- Marine Stewardship Council (MSC) Fisheries Standard (version 2.1, 2018)

- GMP+ B2 Production of Feed Ingredients Standard

- Feed Materials Assurance Scheme (FEMAS) Version 2.1)

Note: These Standards/Programmes are currently recognised under MarinTrust Standard Version 2.

Further information regarding the recognition held by the Programmes/Standards can be found below.

Chilean PAC was formally recognised under MarinTrust Programme in 2019. The Chilean PAC was benchmarked against Section 3.2 of the MarinTrust Standard to determine the Extent of Equivalence in August 2019. The outcome of the benchmark exercise showed that factories certified to the Chilean PAC can be considered to have met requirements equivalent to almost all of those set out in the Section 3.2 of the factory clauses of MarinTrust Standard.

The annual summary of changes submitted by Chilean PAC in 2022 showed substantial changes to the Section 3.2 of the factory clauses , therefore, a full review of equivalency was required for the Chilean PAC to determine if recognition should be maintained. Following the full review of equivalency (refer to Chilean PAC recognition Summary 2022) , MarinTrust submitted to the Governing Body Committee (GBC) the approval recommendation for the continued recognition of the Chilean PAC on 4th October 2022. The GBC agreed with the recommendation and the Chilean PAC is formally recognised.

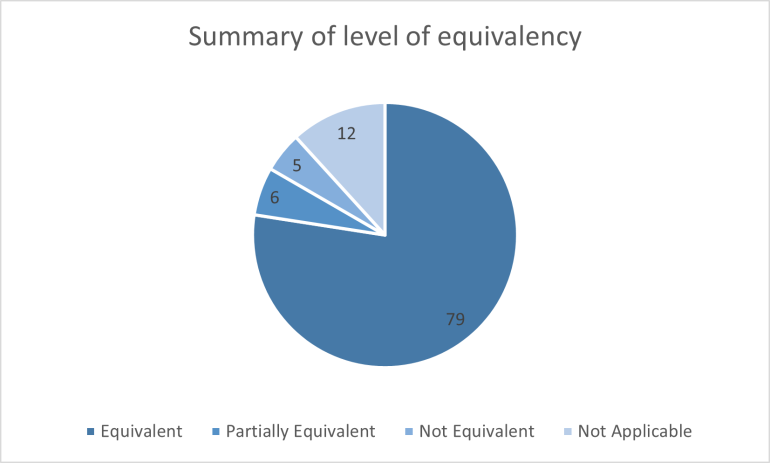

Below diagram provides a visual overview of the level of equivalency of Chilean PAC to MarinTrust factory standard:

Marine Stewardship Council (MSC) Fisheries Standard Version 2.0 was formally recognised under the MarinTrust Programme in January 2021. The MSC Fisheries Standard version 2.0 was benchmarked against the MarinTrust whole fish fishery assessment requirements V 2.0.

The results of the benchmark exercise demonstrated that MSC Fishery Standard is equivalent to the requirements of the MarinTrust fishery assessment V 2.0.

MarinTrust therefore offered a formal recognition of MSC certified fisheries depending on:

- the raw material type.

- MSC claim held by the facility.

How we handle MSC recognition

Step 1

The applicant or certificate holder informs MarinTrust (via application form or scope extension) about their intention to use raw material (wild caught whole fish and/or by-product) sourced from an MSC-certified fishery.

Step 2:

MarinTrust carries out various checks to verify if the raw material is from an MSC-certified fishery and within MarinTrust certification scope.

Where the applicant/certificate holder submits an MSC Chain of Custody (CoC) certificate, MarinTrust will do checks to confirm:

- the certificate is for the facility

- the certificate for the facility is valid

- the species listed on the certificate match the application form

Step 3: Following the checks, where it is confirmed that:

- The raw material comes from an MSC-certified fishery within the MarinTrust certification scope and has a valid MSC CoC certificate, then the raw material will be automatically recognised.

- The raw material is MSC-certified within the MarinTrust certification scope but does not have a valid MSC CoC certificate, the raw material is required to undergo MarinTrust verification and will be recognised provided the verification outcome is 'pass'.

- The raw material is not from an MSC-certified fishery within MarinTrust certification scope and has no valid MSC CoC certificate, the raw material is required to undergo MarinTrust assessment against the MarinTrust fishery or by-product assessment criteria.

For further information about MarinTrust MSC verification process, please click here.

Changes to status of MSC certified material

The status of a fishery and/or by-product can change at any time and this includes MSC-certified material which is within MarinTrust certification scope.

Withdrawn MSC-certified raw material

If the recognised MSC-certified fishery loses its certification, then any raw material from that fishery will lose its MarinTrust recognition and will be required to undergo a MarinTrust assessment for it to be considered as MarinTrust approved raw material.

Suspended MSC-certified raw material

Suspension of MSC fisheries can either be :

- Full suspension or

- Partial suspension

For full suspension of the MSC certificate, the recognised raw material will automatically lose it's MarinTrust recognition and and will undergo a full MarinTrust assessment for it to be considered as MarinTrust approved material.

For partial suspension, e.g. one or more Units of Certification are suspended in the MSC certificate, the applicant/certificate holder is required to:

- Check which raw material species are affected.

- Ensure appropriate segregation is in place to avoid the use of any suspended raw material.

Any species which is not affected by the partial suspension can retain the MarinTrust recognition and the facility can continue to use those species.

Species affected by the partial suspension will automatically lose its recognition and will be required to undergo a full MarinTrust assessment for it to be considered as MarinTrust approved raw material.

Note: Where a certificate holder or applicant requests a MarinTrust assessment for a raw material which has lost its MarinTrust recognition, there is no guarantee that the fishery/by-product will be approved.

Key responsibilities

Applicant or certificate holder using recognised MSC-certified raw material is required to:

- Notify their chosen Certification Body and MarinTrust of any changes to the certificate status of the MSC-certified fishery including suspension and withdrawal of a Unit of Certification or the certificate.

- Confirm if the suspension of a raw material is either a partial or full suspension.

- Ensure appropriate segregation is in place to prevent the use of any suspended and/or withdrawn raw materials.